New cage welding machine BSM – For the production of reinforcement cages for concrete pipes, jacking pipes and manhole rings

Tracey, headquartered in Enniskillen in County Fermanagh, Northern Ireland operates in all pipe markets across Northern Ireland and England. As a market leader, Tracey is committed to exceed expectations providing infrastructure solutions. When Tracey noticed how much the economy was growing, they decided to expand their manufacturing centre. The state-of-the-art factory produces concrete pipes, jacking pipes and concrete shaft rings using the latest technology and delivers its products to Ireland and the UK.

The story of Tracey

Tracey Concrete is one of the largest manufacturers for prefabricated concrete parts in the UK and Ireland. They provide an extensive range of high-quality products and offer competitive and reliable solutions to meet all customer needs.

Tracey Concrete’s success is based on the consistent quality of their products, efficient delivery and outstanding customer service. With the vast experience and expertise in the construction industry, they were able to win some of the biggest projects in the UK and Ireland.

Tracey Concrete is the market leader in concrete pipes, concrete shaft rings, jacking pipes and other products.

Their products have all the necessary certifications and are approved to the latest UK and European standards. Through extensive research the professional engineering team is always on the lookout for the most advanced innovations in the industry and works closely with customers and suppliers.

Equipment for the production of reinforcement cages

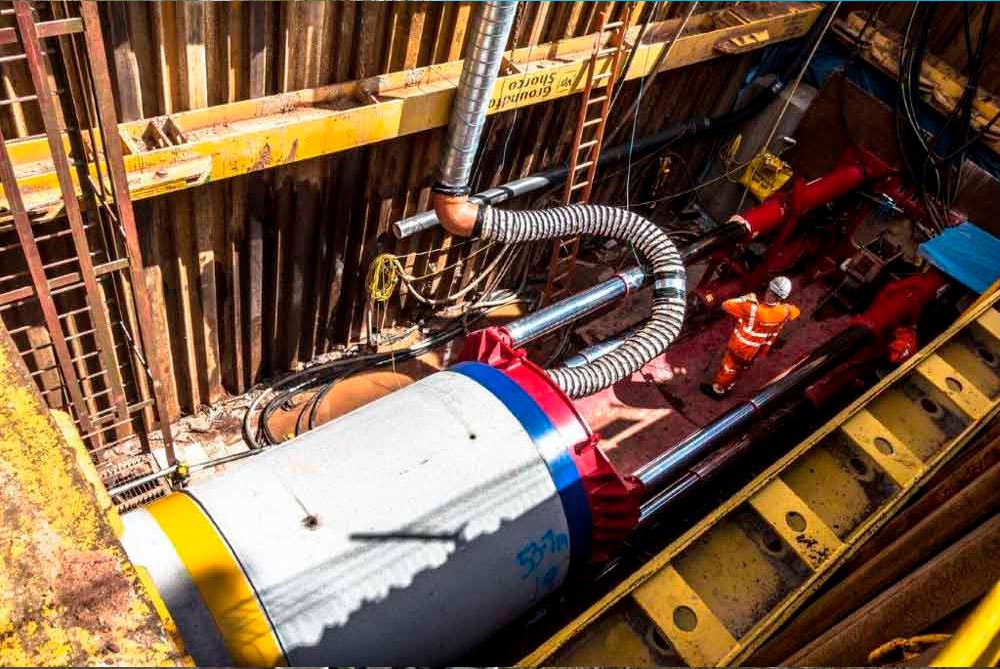

The reinforcement cages in Tracey’s pipes are consistently welded from the peak to the socket.

Tracey has been using cage welding machines from the German company mbk Maschinenbau GmbH since 1994, which they have chosen for its global reputation, excellent after-sales services and its solid and modern technology. In the summer of 2016, Tracey decided to modernize and expand its pipe and jacking pipe product portfolio, once again trusting its strong reinforcement solutions partner. mbk is characterized by a very high reliability and consistent quality. The BSM cage welding machines guarantee high productivity, flexibility and low maintenance and energy costs. The enormous cage diameter area of the BSM-360-R starts at 330 mm and ends at 3,600 mm. The dimensions for the inner and outer cage are easy to change by the touch of a button. Wire combinations of 4-10 mm (optional up to 14 mm) on the longitudinal wire as well as 4-12 mm (optional up to 16 mm) on the winding wire are possible.

The number of longitudinal wires varies from 6, 12 respectively 24, with lengths of up to 3,000 mm and is the guarantor for exact and straight cages. The easy handling and programming of cages with peak and socket with longitudinal wire diameter 4-8 mm make the production a piece of cake. The winding wire spacing is easily customizable depending on the project requirement. Direct communication with the mbk service team is possible via a LAN/Wi-Fi connection. This optimizes the after-sales service.

After the installation at the beginning of 2017 and the intensive training by the mbk team, the production was started directly and the specified performance was achieved in the shortest possible time. The modernization and expansion resulted in a significant increase in quality and production speed. The optimized further processing of the mbk cages sets new quality standards in pipe/jacking pipe production.

With innovations and the modernization and expansion of its portfolio, Tracey Concrete is setting sustainable trends for the market of the future