Automation solutions

Automation solutions for our mesh welding machines.

Automation solutions for the cage welding machine type VSM-S and VSM-V.

Automation solutions for cage welding machine type BSM and BSM-ROR.

MSM-Automation

Automation solutions for our mesh welding machines from simple automation accessories to fully automatic production lines with buffer solutions and connection to downstream systems

Akkordeon Inhalt

Characteristics and Accessories

- Storage systems for line and cross wires for pre-assembly of the wires from coils

- Automatic feeding of the pre-assembled line wires in the machine

- Fully automatic feeding of line and cross wire from bundle or coil

- Connection of a single or multiple wire straightening and cutting plant (DRA-E, DRA-M) for automatic feeding of longitudinal and cross wires

- Increased performance through multi-transformer/ welding stations

- Medium-frequency welding systems (inverter technology)

- Various designs and solutions for mesh ejection and stacking of the mesh

- Options for handling and space-saving mesh turning incl. buffer solutions

- Tilting table and vertical conveyor for the reinforcement mesh

- Fully automatic production of reinforcements for boxes (MSM-Box-Line)

- Automatic bending unit with supporting transport trolleys

- Single bender, multiple bender or complete bending machines in horizontal or vertical arrangement for integration into machines and plants

- Label printer (text or barcode) with automatic labelling

By loading the video, you agree to YouTube’s privacy policy.

Learn more

By loading the video, you agree to YouTube’s privacy policy.

Learn more

By loading the video, you agree to YouTube’s privacy policy.

Learn more

By loading the video, you agree to YouTube’s privacy policy.

Learn more

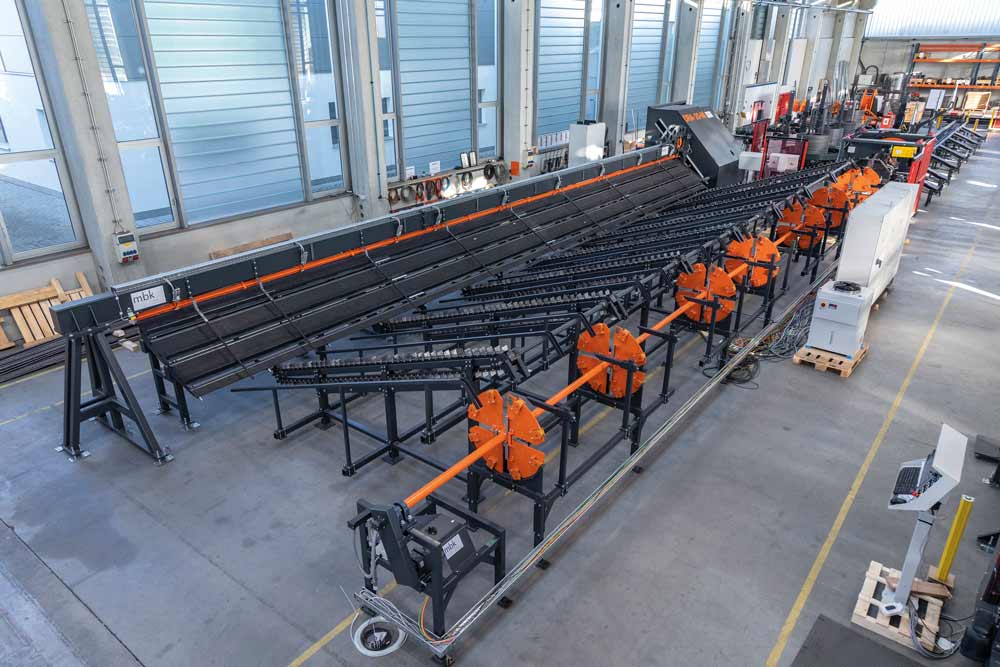

VSM-Automation

Automation solutions for the cage welding machine type VSM-S and VSM-V from simple automation accessories to fully automatic production lines with buffer solutions

Akkordeon Inhalt

Characteristics and Accessories VSM-S:

- Longitudinal wire storage systems for pre-assembling the wires from the coil

- Quick-change system for the product discs

- Processing station after removal of the reinforcement

- Automatic removal of the finished product for further processing

- Buffer storage system with positioning of the products for removal by crane

- Connection of a multiple wire straightening and cutting system (DRA-M) for pre-assembly of the longitudinal wires

Characteristics and Accessories VSM-V:

- Connection of a multiple wire straightening and cutting system (DRA-M) for pre-assembly of the longitudinal wires

- Quick adjustment to reduce changeover times when changing the diameter

- Integration of a feeding device to allow the welding of a narrow wrap with short longitudinal wire projection

- Chain conveyor as buffer and feeding of the longitudinal wires into the machine (automatic loading also possible via wire straightening and cutting machine DRA)

- Processing station after removal of the reinforcement

- Automatic removal of the finished product for further processing

- Buffer storage system with positioning of the products for removal by crane

By loading the video, you agree to YouTube’s privacy policy.

Learn more

By loading the video, you agree to YouTube’s privacy policy.

Learn more

By loading the video, you agree to YouTube’s privacy policy.

Learn more

By loading the video, you agree to YouTube’s privacy policy.

Learn more

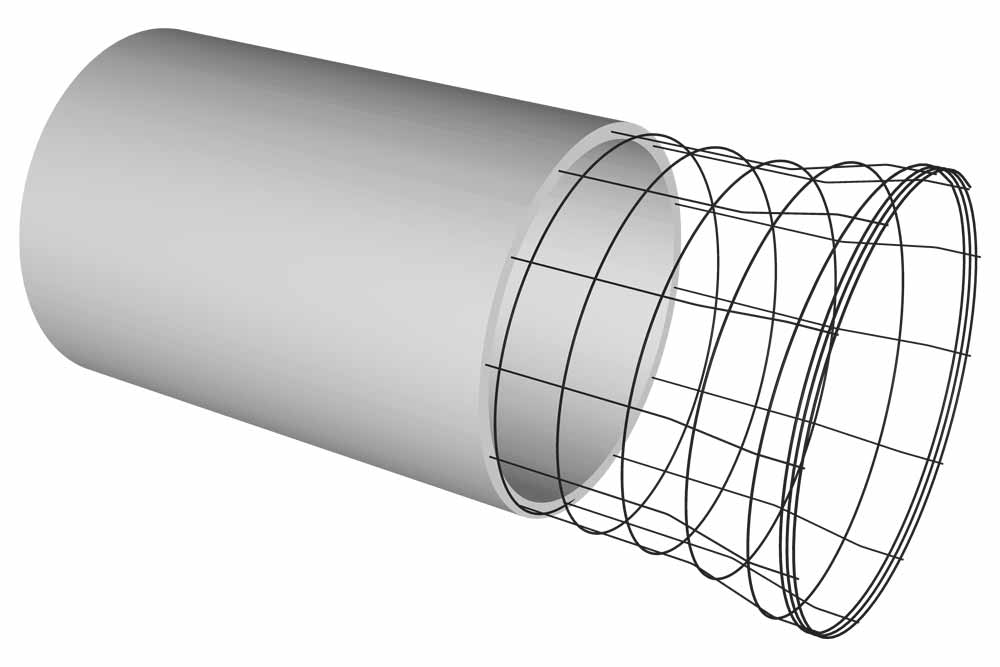

BSM-Automation

Automation solutions for cage welding machine type BSM and BSM-ROR from simple automation accessories to fully automatic production lines with buffer solutions and transfer of the reinforcement to the pipe machine

Akkordeon Inhalt

Characteristics and Accessories

- Motorized wrap wire decoilers

- Automated longitudinal wire feeding for pre-cut wires from bundle

- Wire straightening and cutting units for the production and automated longitudinal wire feeding from coil

- Automated wrap wire changeover

- Automated wrap wire cutter

- Cage removal robots for the automated removal and handling of the cages

- Cage removal and joining robot for the automatic removal, handling and joining of double cages

- Buffer solutions for the storage of reinforcements

- Transport solutions for transferring the reinforcement cages to the pipe machine

- Various software solutions such as:

– Connection of the machine software to the office workstation

– Production list creation

– Logging of all machine parameters and settings

– Logging and saving of production data

– Customer requirements

By loading the video, you agree to YouTube’s privacy policy.

Learn more

By loading the video, you agree to YouTube’s privacy policy.

Learn more

By loading the video, you agree to YouTube’s privacy policy.

Learn more

By loading the video, you agree to YouTube’s privacy policy.

Learn more

By loading the video, you agree to YouTube’s privacy policy.

Learn more

By loading the video, you agree to YouTube’s privacy policy.

Learn more

By loading the video, you agree to YouTube’s privacy policy.

Learn more

By loading the video, you agree to YouTube’s privacy policy.

Learn more