Benefits for the manhole and concrete pipe industry

The requirements of the concrete industry are increasing.

mbk Maschinenbau GmbH usually succeeds in developing machine concepts in advance that ensure rational and economical everyday production. Solutions with added value are created on 10,000 m2 at the headquarters in Kisslegg.

In addition to top quality and a high degree of individualisation of the machines, mbk also focuses on achieving the highest possible savings potential in terms of material and production processes. This is achieved, among other things, through tailor-made automation solutions, which play a significant role at mbk.

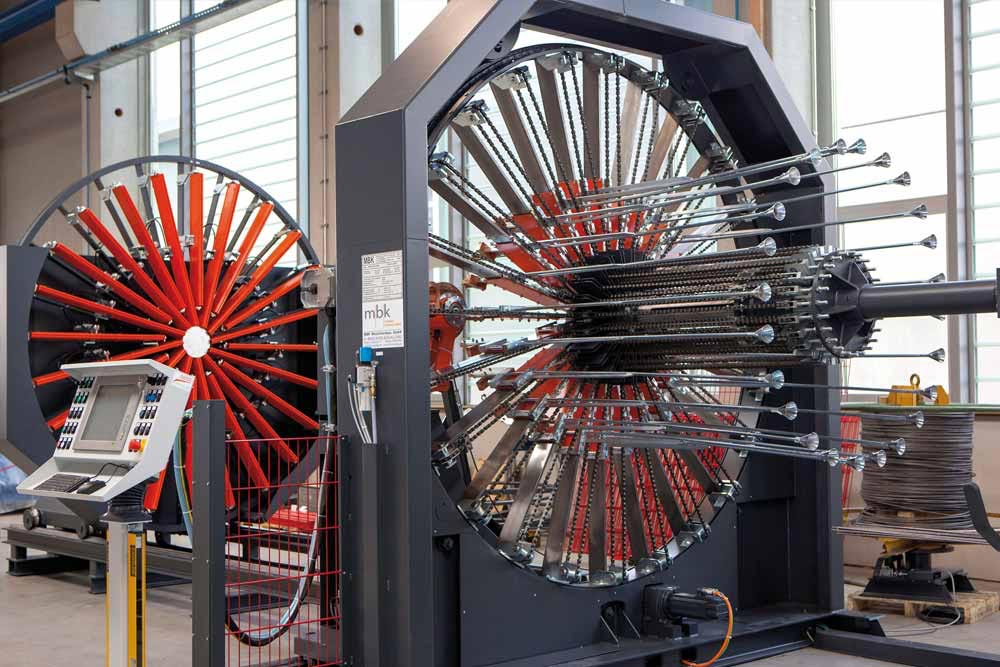

For the production of various manhole and concrete pipe reinforcements, mbk has cage welding machines with a wide range of specifications in its range.

ROR cage welding machine with variable spread

When round concrete components are produced (e.g. for wastewater piping systems), round concrete elements are inserted into the mould during pipe production. Since concrete is enormously pressure resistant but not resistant to strain or bending, different stress ranges arise in a concrete pipe – depending on the installation condition – which must be supported differently. As it was not possible until recently to produce reinforcement cages with different geometric shapes (e.g. round-oval-round) on one machine, two round cages with different diameters were used. With one reinforcement cage the tensile stresses in a certain pipe area were absorbed and with the second cage the stresses in another area, which are usually offset by 90°, were absorbed. The result was not only disproportionately higher costs (and masses) for the respective products, but also a noticeable additional expenditure in terms of time and handling.

mbk’s know-how was in demand and the BSM-ROR was born – a cage welding machine with which cages with variable, interlocking geometry can be produced. In the production process, reinforcement cages flow smoothly from one shape to another shape and then back again (e.g. round-oval-round). The tensile stresses, which are offset by 90° in different diameter ranges, are only absorbed by one reinforcement cage. Responsible for this is the development of a spreading system in which the linear movement of a spreading drive is divided into different linear movements of the individual slides, each holding a longitudinal wire.

A special challenge was also the hydraulic control system of two hydraulic drives, some in synchronous and some in counter-rotating operation.

Oval reinforcements were, of course, already known and corresponded to the current state of the art. However, pipes with oval reinforcement as central elements have no support in the connecting elements of the pipes (socket and bell). These connecting elements must be round for reasons of tightness. Thus, round reinforcements at the ends of the pipes are indispensable for a stable, fatigue-resistant and tight concrete pipe. The BSM-ROR is mbk’s answer to the demands of an innovative market and offers economic advantages such as enormous material and time savings, handling and maintenance benefits as well as a significant added value for the environment: Saving of steel resources (45%), energy saving, reduction of traffic volume.

BSM cage welding machine

The BSM cage welding machine for the production of reinforcement cages for the manhole and concrete pipe industry is also available in the following versions: round (with bell socket), double cages one behind the other, oval (round, with bell socket), oval, egg shape, open shape or in special shapes. The BSM is available in eight sizes, the producible cage diameters ranging from 220 – 1,700 mm to 900 – 5,200 mm, depending on the machine type. The cage lengths range from 2,000 – 7,000 mm, other lengths are available on request. The BSM is very reliable and durable. In addition to a stable design, it is distinguished by high productivity, flexibility and low maintenance and energy costs. Changes of dimension at the push of a button and link programs for inner and outer cages. Strictest production tolerances for exact and straight cages and their compatibility with any standard make the BSM highly suitable for everyday use. Numerous additional features guarantee stable production processes. A wide range of optional automation solutions improve the daily production routine.

BSM Automation

The automation solutions for the BSM and BSM-ROR cage welding machines range from simple automation accessories to fully automatic production lines with buffer solutions and transfer of the reinforcement to the pipe machine.

A wire straightening and cutting machine is used to produce longitudinal wires. Wrap wire decoiler with and without drive, multiple winding wire guides for quick wire change. The automatic longitudinal wire feed with wire from the bundle or from the coil. The automatic wire wrap cutter is also part of an automation solution. Appropriate aids are available for handling the manufactured products, such as a cage removal carriage and cage removal devices. Removal, placement, positioning and joining of reinforcements and double reinforcements by means of cage removal and joining devices.

Buffer solutions optimise the storage of reinforcements.

Modern transport facilities were designed in order to ensure the safe transfer of the reinforcement to the pipe machine.

Various software solutions such as machine software for office connection, production lists in the office, recording of all machine parameters, settings and production data simplify and accelerate the production performance noticeably.

ISM cage welding machine

The ISM cage welding machine was designed to produce reinforcement cages flexibly and economically. Like all mbk machines, the ISM meets all requirements for reliability, durability, energy saving and low maintenance.

With the ISM, cages in the round version (with bell socket) can be produced in the following diameters (depending on the machine type):

220 – 1,400 mm (140)

220 – 1,900 mm (190)

330 – 2,500 mm (250)

660 – 4,500 mm (450)

Cage lengths can be realised from 2,000 – 3,000 mm, other lengths are available on request.

ISM also stands for strictest production tolerances and guarantees the production of exact and straight cages. The scope of delivery includes wrap wire decoilers up to 3 t as well as a switch-off ramp with monitoring for wrap wire decoilers. A wire deflector as well as wire guiding stands, a cage removal carriage in the standard / electro-hydraulic version and corresponding machine tools complete the offer.

The ISM is easy to operate (no PC knowledge required), which allows it to be integrated quickly and easily into an existing production environment.

ESM cage welding machine

The ESM has long since established itself in the manhole and concrete pipe industry and is used when round (with socket), double cages in a row are required. With its possible cage diameters of 220 – 1,900 mm, 330 – 3,000 mm and 330 – 3,600 mm, it meets the requirements reliably, economically and with very high production accuracy.

Wrap wire decoilers with and without drive, a switch-off ramp with monitoring for wrap wire decoilers and medium frequency welding (3-phase inverter technology) are some of the special aspects. Die LAN-/WLAN-Anbindung erweitert ihr Einsatzspektrum. The LAN/WLAN connection extends its range of applications.

Being at the forefront means keeping an eye on the future of the markets – all over the world: to know where the journey is going and to react accordingly to this dynamic.

If experience and know-how are added to empathy, solutions are created that can be more than just trend-setting.

https://youtu.be/MwUF9no9hng

By loading the video, you agree to YouTube's privacy policy.

Learn more