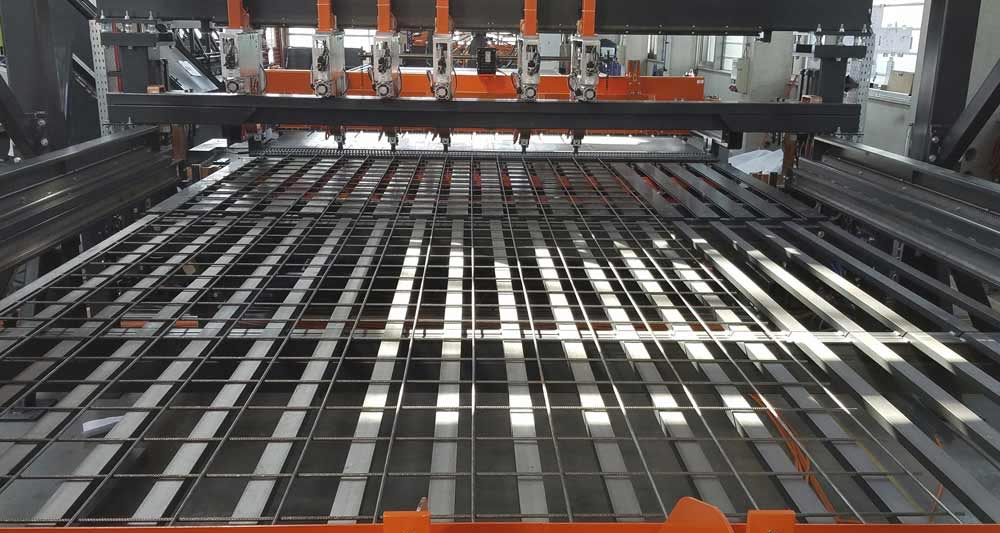

Further developed mesh welding machine for precast slabs with in-situ topping and solid walls

As a system solution partner, mbk Maschinenbau GmbH’s product range also includes a modern mesh welding machine for the production of precast slabs with in situ topping concrete with Z-bending (BF4) and meshes with recesses for solid walls (double walls) as well as special and standard meshes. The line is equipped with technical innovations such as a mesh conveyor system for different depositing positions and stack formation according to the pallet layout. In addition, the reinforcement welding machine MSM-M capable of providing the meshes flexibly – according to customer requirements – and to place them on the pallet just-in-time.

mbk develops, designs and implements efficient and reliable solutions for the construction, concrete and precast industry with a highly expertise development and technical team at its headquarters in Kisslegg, Germany, located on a site of circa 10,000 m2.

In addition to know-how and experience, innovative strength also means integrating the needs and requirements of customers into a modern production environment. mbk reacts to the changes in the market with new, contemporary approaches (and designs).

A highly automated precast production of precast walls, double walls and slabs requires efficient and intelligent reinforcement production. The main area of application of the meshes produced is in precast concrete elements for building construction, residential and industrial construction. In particular, the automated production of reinforcement meshes for the manufacture of precast concrete elements with recesses for window and door openings, for walls and recesses for ceilings is becoming increasingly important.

The flexible mesh welding machine MSM-M welds reinforcing steel meshes directly from the coil – set to individual CAD drawing specifications. The mesh width that can be produced on the machine shown is in the range of 500 mm to max. 3,500 mm, depending on the requirements. The mesh length ranges from 1,000 mm to 8,000 mm. Since the system is manufactured to customer specifications, larger dimensions, both in length and width, are also possible.

mbk’s DRA-M multiple rotor straightening and cutting machine is used for the automatic loading of the longitudinal and transverse wires for flexible mesh production from the coil. The standard wire diameters to be processed range from 6 mm to 16 mm and can optionally be be adjusted from 5 mm to 20 mm. In this version, the wires are fed in via 5-tonne reels, alternatively 3-tonne reels can be used.

The longitudinal reinforcement is transferred fully automatically directly from the DRA-M rotor straightening and cutting machine to the welding unit of the mesh welding machine. The grid size of the longitudinal reinforcement is 25 mm.

The automatic provision of the additional reinforcement by means of DRA-M on a separate run-off carriage is another useful accessory function.

The required lengths of the transverse reinforcement are assembled with the DRA-M and then fully automatically transferred to the welding unit of the mesh welding machine as required. The minimum distance between the cross wires is 35 mm and can be adjusted with no upper limit.

Once the mesh is finished, it is automatically labelled with text and/or barcode as required, the information required for this coming directly from the host computer. A mesh conveyor system enables further processing via a fully automated traverse. The mesh is transported automatically – depending on the application – for further processing to the bending beam for Z-bending the end bars (BF4) or directly to the stacking position. In the subsequent circulation plant, the mesh is deposited and stacked at the respective positions for further processing – as in the pallet layout – according to the master computer specifications.

This further development of the MSM-M mesh welding machine from mbk also meets the requirements of everyday suitability and within budget. With the usual stable and solid construction made in Kisslegg and low maintenance requirements, mbk guarantees efficient production processes.

The production capacity of the MSM-M corresponds to the production requirements of the customer’s pallet circulation system and is dependent on the layout and recesses. The MSM-M is developed and built in different performance levels and with various accessories for automation according to individual customer requirements. The plant layout is flexible and can be adapted to local conditions. In this MSM-M mbk implements stacking for buffering in the reverse order: The meshes are prepared for production in different stacks in the areas assigned by the master computer. The stacks of meshes are then provided just in time for the circulation plant by means of a chain conveyor. For series and end stirrup production there is also the possibility of producing special and standard meshes.

The equipment of the plant with a mesh bending station for frontal Z-bending (BF4) of the bar overhangs is predetermined for the production of precast slabs with in situ concrete topping. The automated traverse allows the produced boards to be deposited for external purposes on an additional stacking pallet. These can then be used for other purposes such as structural precast elements and additions for the construction site.

The strength of mbk lies in the development and realisation of individual, modern and future-oriented solutions according to the actual situation of the customer and the respective requirements profile. Our professional spare parts and maintenance service is also one of the company’s focal points.

At mbk Maschinenbau GmbH these qualities are part of our ethos and customers all over the world appreciate this.

Because, even in a world dominated by technology, values shape customer relationships (strong connections) determine how market shares develop. https://youtu.be/1mgbCBe9CzI

By loading the video, you agree to YouTube's privacy policy.

Learn more